Optical Layout

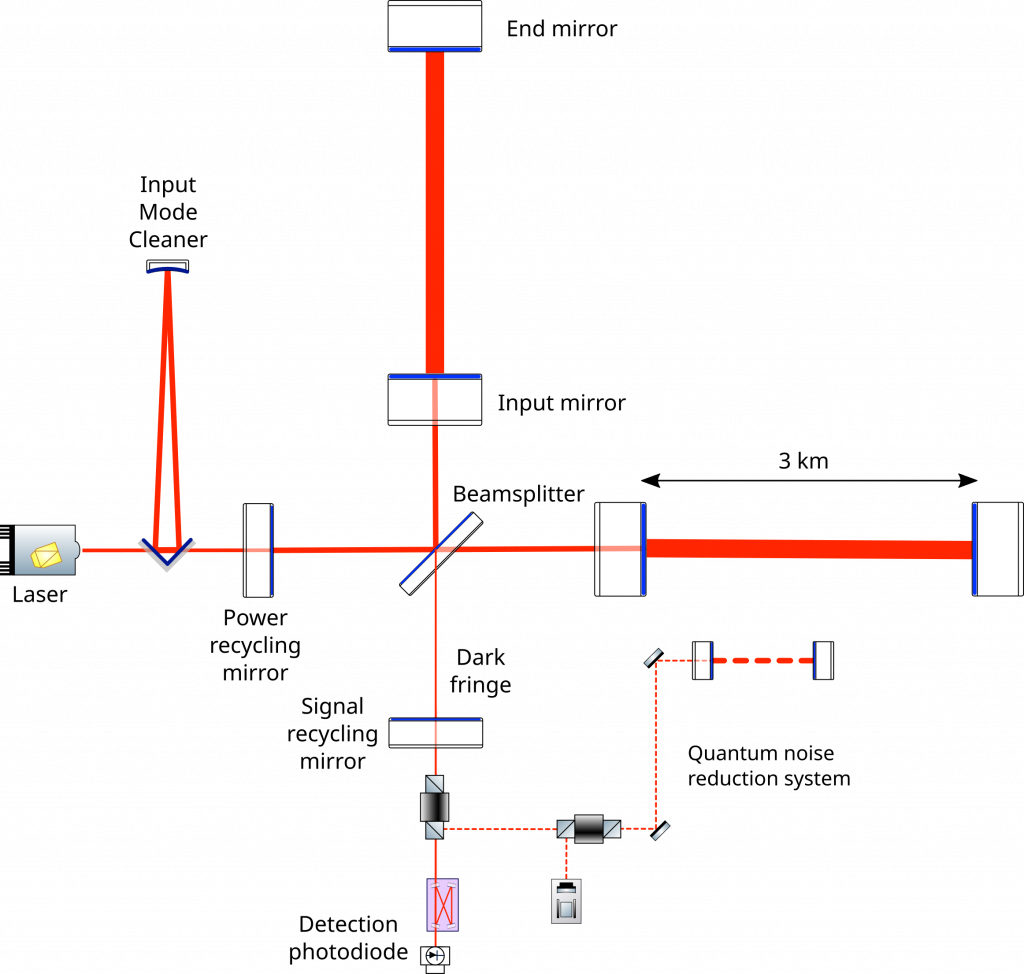

Advanced Virgo is a laser interferometer with two 3 km-long perpendicular arms. This instrument, in this configuration, is ideally suited to measuring the tiny effect produced by gravitational waves as they pass through the detector.

The change in the arm’s length caused by the passage of a gravitational wave is proportional to the length of the arm itself, as well as to the amplitude of the wave. This means that the longer are the arms of the detector, the larger is the signal we need to measure and this makes the detection less difficult.

Fabry-Perot Cavities

As mentioned above, the arms of Virgo are 3 km long but the laser light traveling within the arms covers a much greater distance before recombining at the beam splitter. In fact inside the arms the light is reflected back and forth, from one end of the arm to the other, 300 times. This is possible thanks to the implementation of optical resonators (called Fabry-Perot cavities) along each arm, and involves adding an extra mirror at the beginning of each arm, close to the beam splitter. Thus each arm has two mirrors: the input mirror, near the start of the laser path, and the end mirror, at the opposite end of the arm.

Because the interferometer works at ‘dark fringe‘, the light that is recombined by the beam splitter after travelling along the arms travels back towards the laser source. Instead of being blocked, such light is reflected back so that it is re-used in the interferometer: this is done thanks to an additional mirror placed downstream between the beam splitter and the laser source. This mirror is named Power Recycling and thanks to it the light power is enhanced by a factor 30. We ‘recycle’ also the gravitational wave signal: this is done by adding one more mirror after the beam splitter, before detecting the interference pattern. This mirror is named the Signal Recycling mirror. Overall, Advanced Virgo is designed to be a dual recycled Michelson interferometer.

The Advanced Virgo optical layout comprises two additional systems: the Input Mode Cleaner and the Quantum Noise Reduction. The first one is needed to improve the quality of the laser beam circulating the interferometer, in terms of beam pointing stability, spatial shape, frequency purity. The second is a complex system to reduce the noises due to the quantum nature of light.

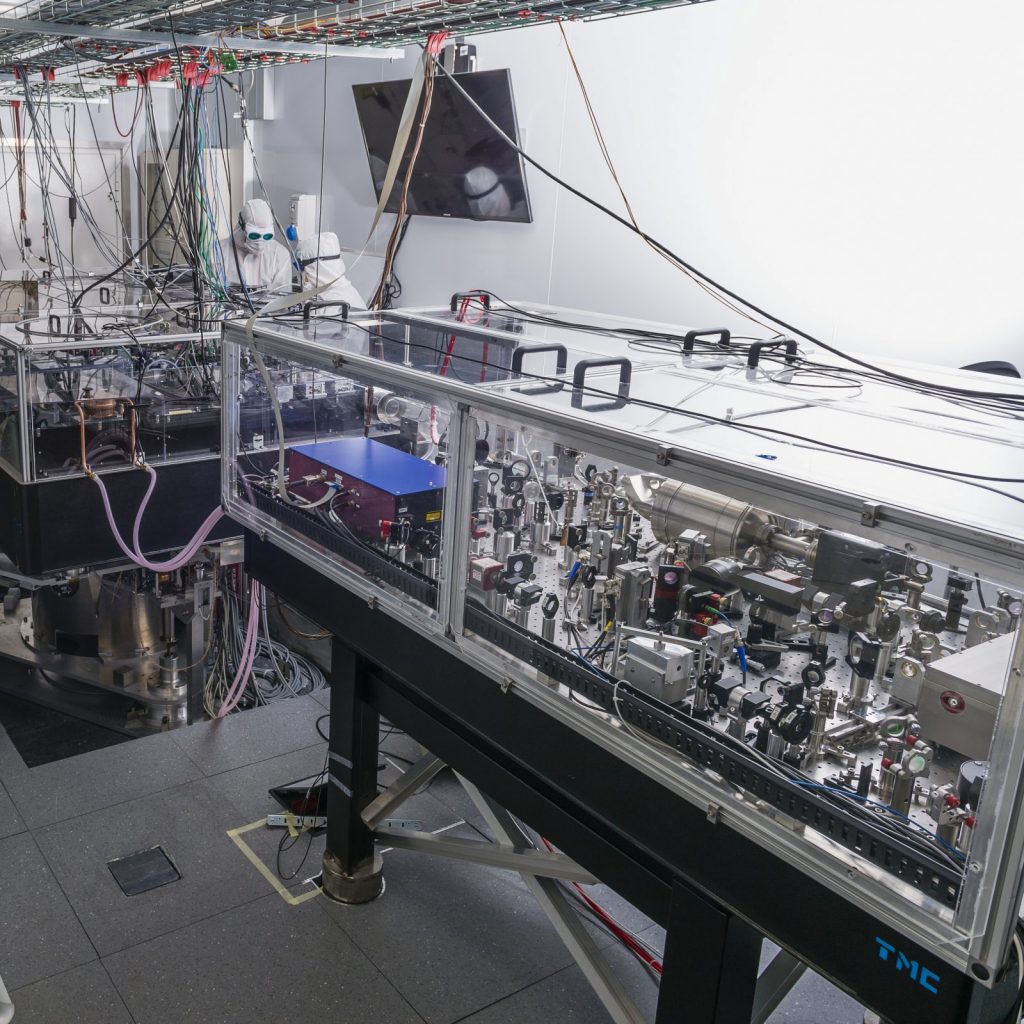

Injection

© Cyril Frésillon/Virgo/Photothèque CNRS

In Advanced Virgo the part of the detector which delivers the laser beam to the interferometer with the required power, size and stability is called ‘the injection’. It comprises all the parts between the infrared laser source (wavelength of 1μm) and the core interferometer and it ensures that the input laser beam will have all the right properties needed for controlling the interferometer with very low noise. One key element of the injection is the 150 m long optical cavity, called the Input Mode Cleaner: its purpose is to guarantee a well-defined laser beam stable in position and shape. Finally, before the recycling cavities, a telescope will enlarge the laser beam by a factor 20 to match the required beam size in the central part of the detector.

Arm cavities

The two optical resonators which are along the perpendicular arms (and called the ‘arm cavities’) give Virgo its characteristic L-shape and are among the most critical components of the detector. Each arm cavity is formed by 2 outstanding mirrors, each 42 kg in mass, one at the input, close to the beam splitter, and one 3 km further which reflects all the light back towards the beam splitter. The cavities are optical resonators in the sense that the light between the two mirrors propagates in multiple round trips, each time enhancing a little more the gravitational signal. For example, in Virgo, the gravitational wave signal is amplified by about a factor 300 thanks to the cavities in the arms.

To enhance the performance of the interferometer the surface of each mirror is polished at the atomic level, reducing the amount of scattered light. The coating on the mirror surface is also special to reflect all the light with very limited absorption and inducing no distortion. These mirrors have been (improperly) called the perfect optics. Thanks to the quality of the mirrors, the amount of laser light lost during one round trip in the cavity (so 6 km) is less than 0.01%.

Detection

In Advanced Virgo the part of the detector which is responsible for extracting the signal encoded on the laser light by the gravitational wave, is called ‘detection’. It also provides a large part of the signals to control the interferometer and keep it at its working point. As for other parts of Advanced Virgo, noise control is critical, so all the optical components for the detection are isolated from the ground motion by suspending the optical benches they sit on: these benches are hosted in vacuum to avoid dust and acoustic noise. At the output of the interferometer, a telescope is used to reduce the beam size by a factor 40 to achieve a laser size compatible with the photoreceivers, called photodiodes. A smaller optical cavity, called the ‘Output Mode Cleaner’, is inserted before the final photodiode where the gravitational wave signal is recorded. This cavity filters the light to remove spurious signals and only transmit the laser light which may contain the gravitational wave signal.